Facilities

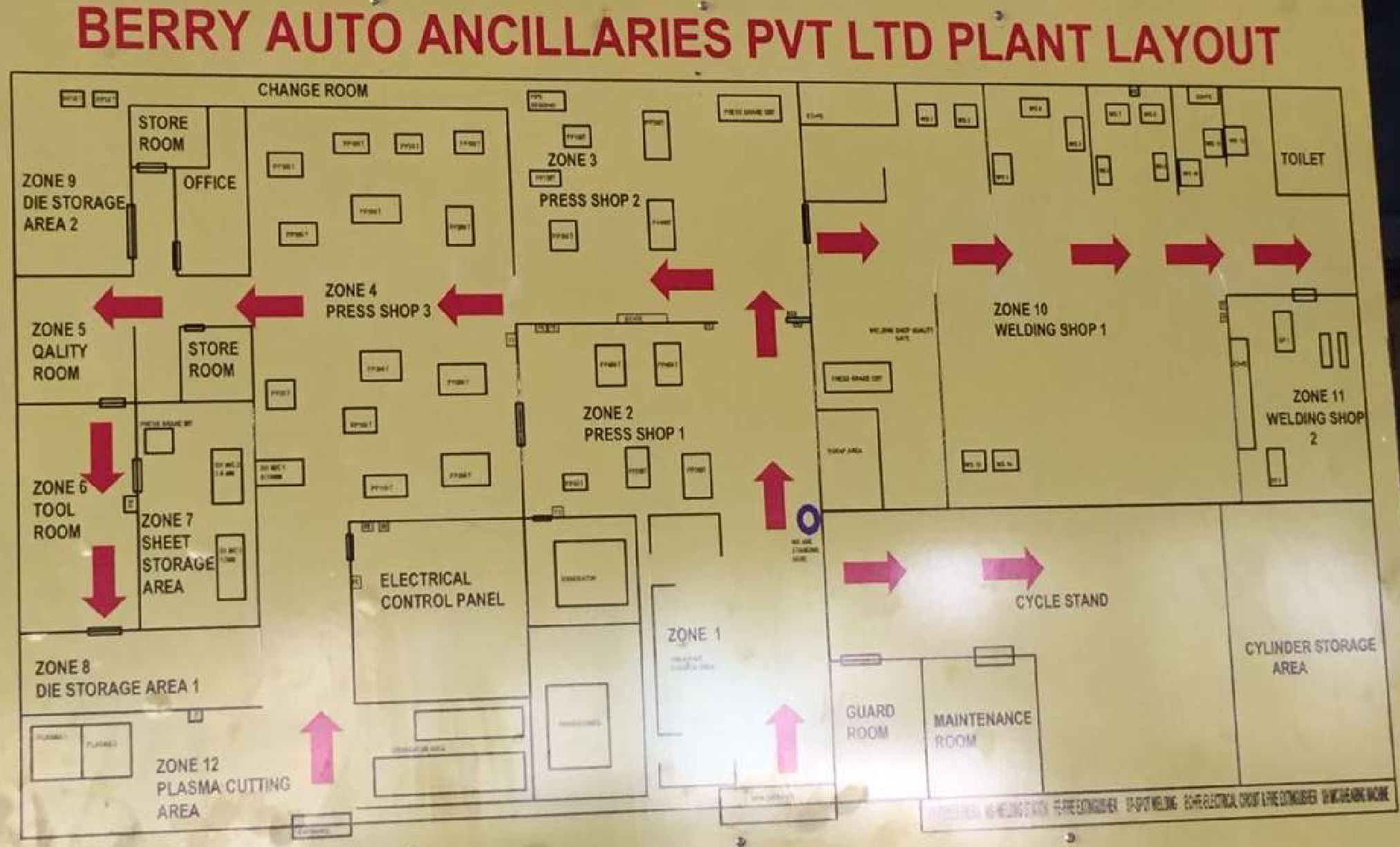

Plant Layout

Training Center

We have our own Training Room to impart due knowledge to our workforce from time to time. The training is from in-house experts as well as from outside source.

We have talented team of engineers, Managers & work force working with us.

We have strict Quality Standards and System to ensure Quality Products.

Die storage area

We have about 3500nos of dies used by us under two sections. One for fast moving & the other section for slow moving components. Color combination used to differentiate dies Customerwise. Mostly all major components have two to three sets of dies.

Tool Room

We have in-house tool room as well as outsourced tool rooms for development and maintenance of tools. Machines like CNC Lathes, CNC Vertical Machining Center, Shaper, Surface Grinding Milling are used by us and our approved die makers.

Powder Coating Plant

We have three Powder Coating Plants of state field make company.

Two installed in Unit-1 / Unit-3

Baking Oven

We have three Baking ovens and furnace PNG(Green gas) fueled and LPG fueled in Unit-1 & Unit-3 conveyorized type.

PDI Area

PDI Areas are well defined in our Unit-1 & Unit-3.

Quality Room

FG Area

FG Areas are defined in our respective units. Minimum inventory to meet contingency requirement of our principals / customers from time to time are maintained.

Logistics

We despatch components to our local customers in specified trolleys and bins in our own vehicles for smooth safe and timely delivery on just-in-time basis.